Industry Stainless Steel Sheet

After World War II, stainless steel was widely developed and used. Stainless steel, as the name suggests, will not rust. Due to its unique corrosion resistance, high hardness, high wear resistance, and bright luster. These properties also distinguish stainless steel from other steels. Industrial stainless steel mainly comes in three forms, plates, coils, and tubes. Based on the forms, various surface treatments can also be processed. Commonly used surfaces are 2B BA NO.4 NO.8 hairline snowflake, etc. The application range of industrial stainless steel is also very wide, including kitchen supplies, building materials, manufacturing equipment raw materials, the chemical industry, the petroleum industry, the automotive field, the 3C field, etc.

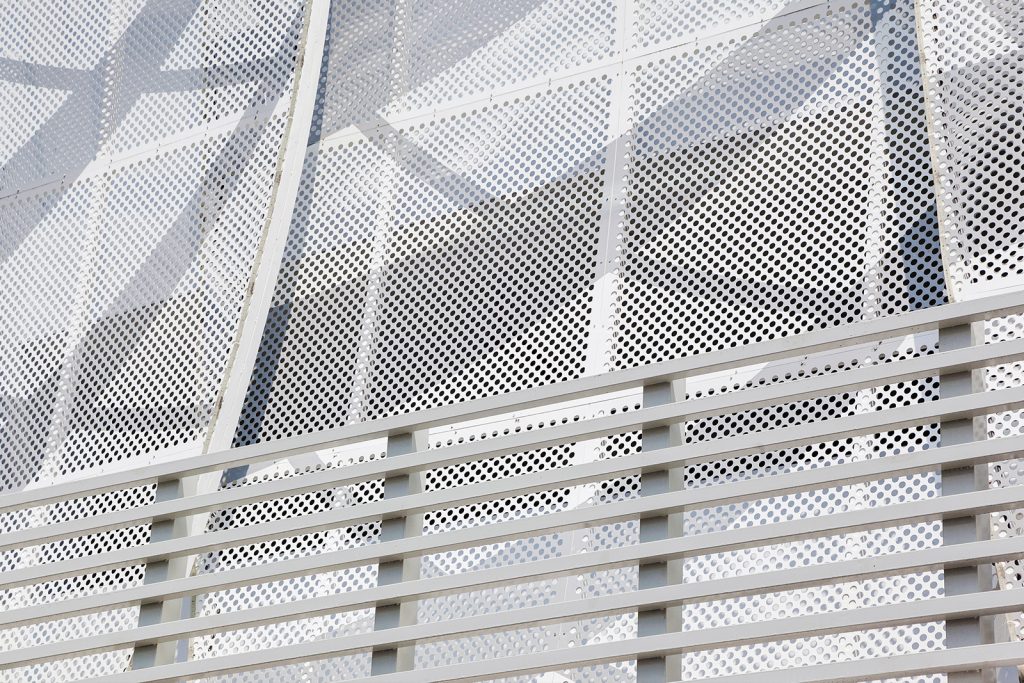

Perforated Stainless Steel Sheet

Perforated stainless steel plate is punched holes on stainless steel plates or other metal through CNC punching equipment, and the size and shape of the holes can be customized. The perforated stainless steel plate has an exquisite appearance and can be applied in a wide range of fields. Our team with rich experience will provide suitable solutions for perforated stainless steel plates according to the customer’s application scenarios and requirements.

CNC Laser Cut Stainless Steel Sheet

Laser cut stainless steel sheet is made through the high-density beam of the laser cutting machine which cuts the pattern on the surface. The cut stainless steel plate has exquisite patterns, no burrs, and no secondary processing. The product can be produced immediately as soon as the material arrives. It has very high processing efficiency and the cost is lower than traditional processing. The laser-cut stainless steel sheet product is mainly used for the customization and processing of metal screens.

Water Ripple Stainless Steel Sheet

The water ripper stainless steel is using stainless steel which already had NO.8 surface finished as raw materials, and then the surface texture becomes similar to water ripples through the punching process. This water ripper stainless steel sheet has a very strong decoration effect. In the past two years, it has been popularly used in bars, restaurants, and exhibition halls with a strong artistic atmosphere. The space decorated with water ripple plates will have richer layers visually. Moreover, the stainless steel plate still retains the characteristics of fire prevention, corrosion resistance, and easy cleaning.

Honeycomb Stainless Steel Sheet

Stainless steel has good rust resistance and its surface remains shiny without excessive maintenance costs. The disadvantage is that if thickness and volume of stainless steel if growing and the weight of stainless steel also increases. Bulky stainless steel plates are no longer suitable as building materials for exterior walls or ceilings. In order to solve this shortcoming, honeycomb stainless steel composite panels came into being. A honeycomb panel consists of three parts. The surface and bottom are stainless steel plates, and the middle is an aluminum honeycomb core. The surface of the stainless steel plate can still retain surface treatments, such as mirror and brushed finish. This is a new type of lightweight and high-strength board, and it is currently the best solution to solve the problem of heavy and uneven surfaces.

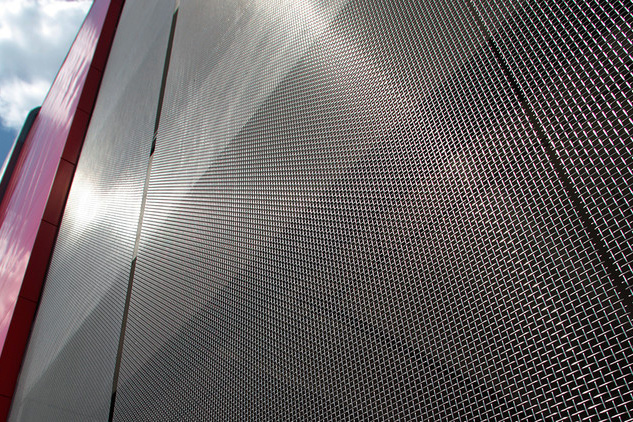

Stainless Steel Wire Mesh Sheet

Wire mesh stainless steel plate is a perforated metal plate that expands to two to ten times the length of the raw material after being processed by precision expanded metal equipment. The expanded mesh size can be fully customized, and different sizes of mesh panels affect its open rate. In this way, the form of raw materials is changed, if, under the same project, construction materials, processing costs, and project lightweight can be greatly saved. The stainless steel wire mesh sheet has visual clarity, which is conducive to lighting and ventilation without affecting its fashion sense.

Stainless Steel Checker Sheet

Stamped Plate refers to the process on the stainless steel plate through mechanical equipment to make the layout appear concave and convex patterns. Various styles, strong three-dimensional sense, wear-resistant, and non-slip are the benefits of the stamped stainless steel plate. It is a perfect choice for elevator floors, cabinet panels, and subway compartments.