Laser cut stainless steel sheet is made through the high-density beam of the laser cutting machine which cuts the pattern on the surface. The cut stainless steel plate has exquisite patterns, no burrs, and no secondary processing. The product can be produced immediately as soon as the material arrives. It has very high processing efficiency and the cost is lower than traditional processing. The laser-cut stainless steel sheet product is mainly used for the customization and processing of metal screens.

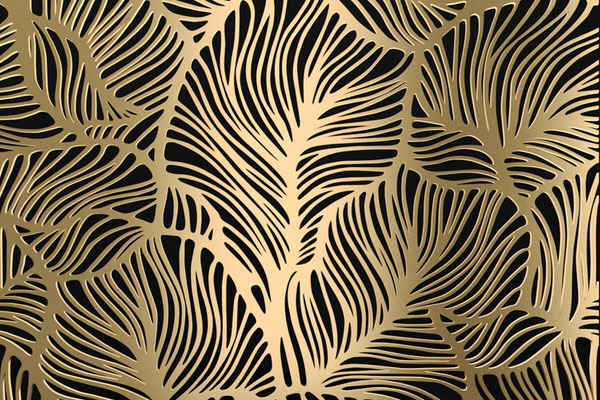

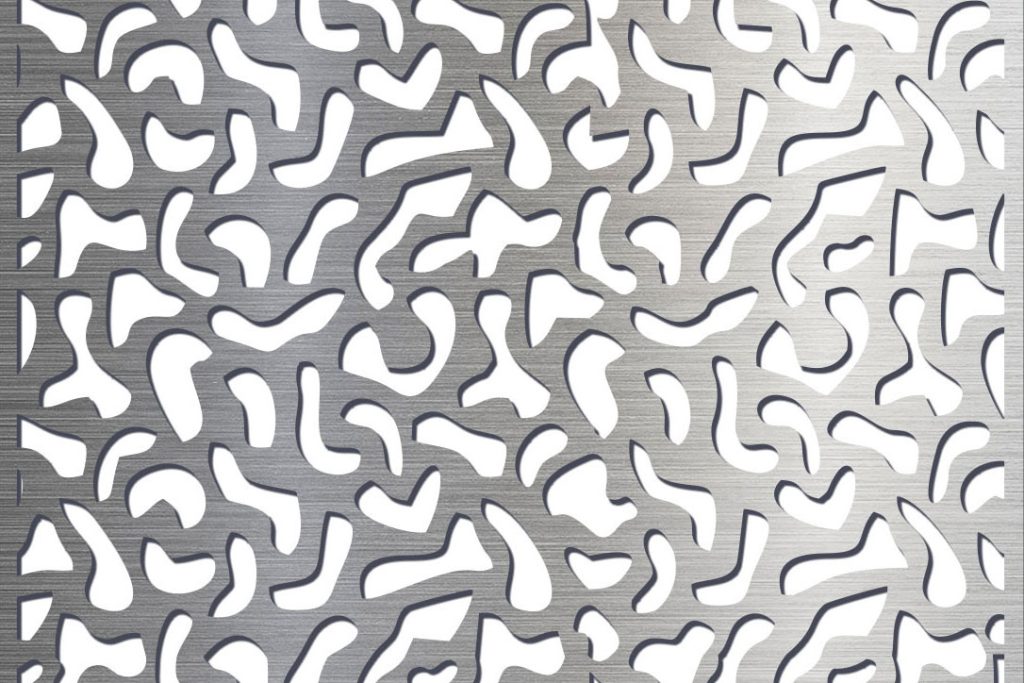

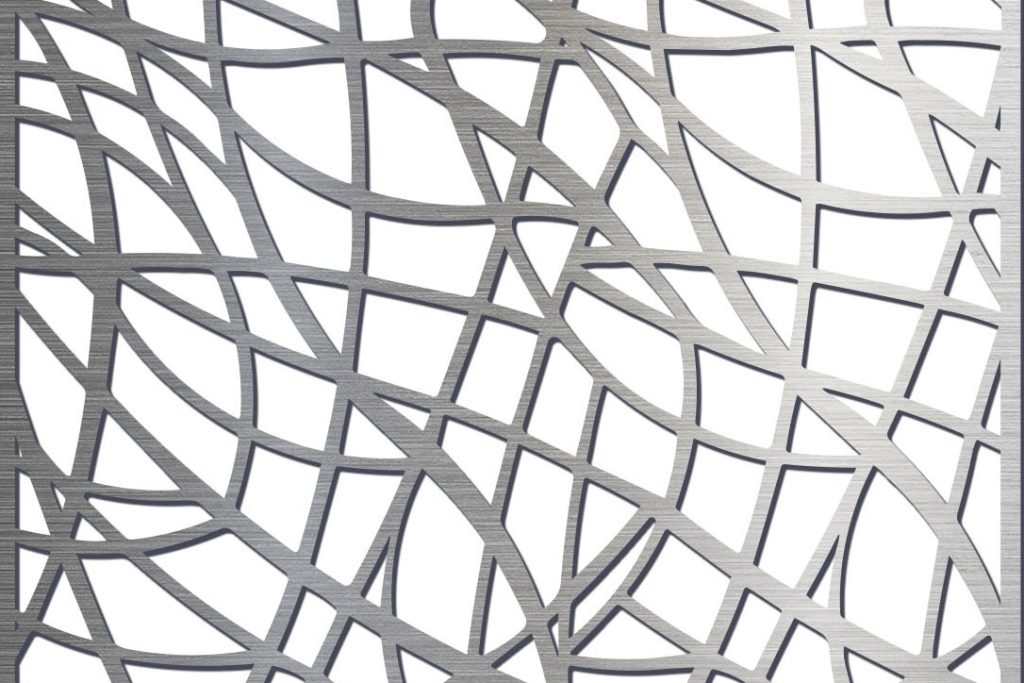

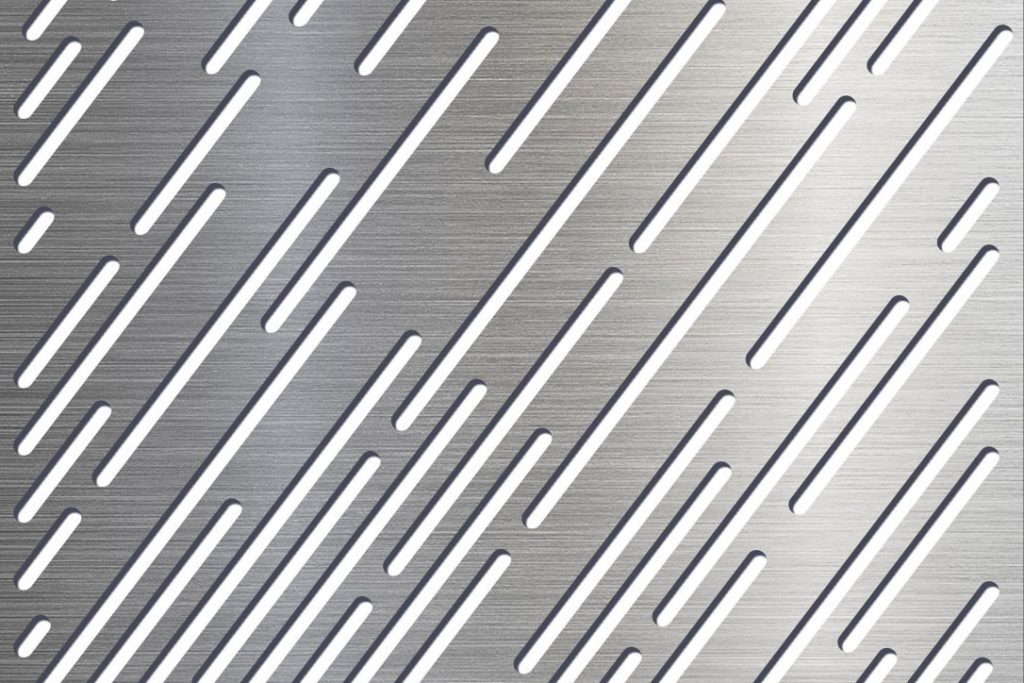

Style Options

Laser-cutting technology opens up a world of design opportunities by intricately carving patterns into various materials. From metal to wood and acrylic, laser-cut patterns add a unique touch to products, decor, and architectural elements, merging precision with artistic creativity.

Specifications

| Standard: JIS, AiSi, ASTM, GB, DIN, EN. | Grade: 304/304L/316/316L/430/201 |

| Thickness: 0.3 mm – 3.0 mm. | Punching: available |

| Width:1000mm, 1500mm, Customized. | Pattern: Customized |

| Length:Customized(Max: 6000mm) | Surface Finish: Mirror/Brush/Sandblasting/ Vibration/Cross-hairline |

| Tolerance:1% | Color: PVD Coating |

Video

Applications

We are deeply involved in the stainless steel sheet and its works industry with 12+ years of manufacturing experience. And participate in 500+ construction projects per year. We anticipate customer needs by understanding what they think and feel. We constantly improve the product system, and provide customers with excellent pre-sales, sales, and after-sales services.

Latest Posts

Process method of water-corrugated stainless steel panel

Process method of water-corrugated stainless steel panel 查看全文 »

What is a stainless steel decorative plate?

What is a stainless steel decorative plate? 查看全文 »

What is a water ripple stainless steel panel?

What is a water ripple stainless steel panel? 查看全文 »

What is a stainless steel mirror plate?

What is a stainless steel mirror plate? 查看全文 »